XPS should not be confused with EPS (expanded polystyrene)

XPS should not be confused with EPS (expanded polystyrene)

Applications for XPS include wall, roof and floor insulation. XPS is particularly suitable for use below ground or for instances with additional loading requirements.

Floors and roofs

Closed cell rigid insulation

Low thermal conductivity

High strength and durability

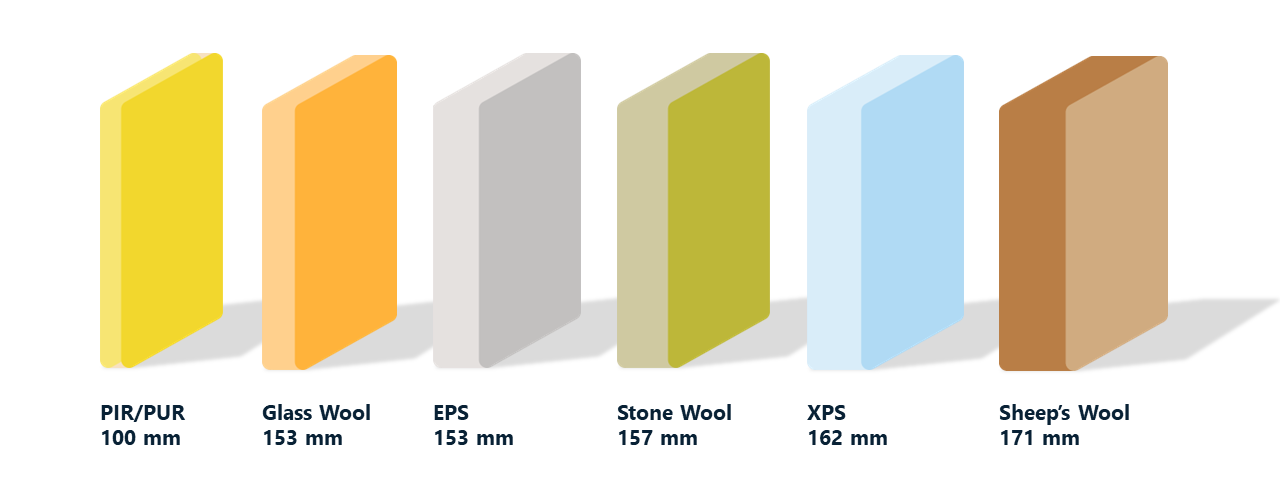

Because of its superior thermal performance PIR insulation offers optimal insulation value meaning a thinner layer will achieve the same insulation properties. This has other benefits, as using thicker insulation will mean a larger building footprint or smaller internal dimensions for a property.

The diagram shows the typical thicknesses of different wall insulation materials needed to achieve an R value of 4.5.

Insulation Manufacturers Association© | All Rights Reserved 2025

Designed & Built By Platform81