Rigid polyurethane (PUR) and polyisocyanurate (PIR) insulation products are highly effective, lightweight and easy to handle. Their excellent thermal conductivity and high strength to weight ratio, combined with great manufacturing versatility provides a wide range of products. As a result, PIR and PUR insulation products are the natural choice for most construction thermal insulation applications.

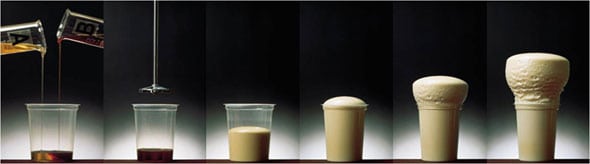

Rigid PUR insulation products are made by reacting a liquid polyol with a liquid polymeric isocyanate known as MDI in the presence of a blowing agent and other additives. The mixed components then react exothermally to form a rigid thermosetting polymer. Since the blowing agent evaporates during this reaction a rigid closed cell low density insulation product is created. Excellent insulation performance is achieved because the gas trapped within the closed cell structure has a very low thermal conductivity and there is minimal heat conduction through the solid cell walls due to the low density. Approximately 97% of the volume of the foam is trapped gas.

Rigid PIR differs from PUR in that it is produced with a slight variation in the chemical components. The resultant PIR insulation products exhibit increased fire performance and reduced combustibility and higher working temperature limits compared to PUR and when incorporated into building products, can meet some of the most demanding industry requirements.

You can find a full list of IMA members here.

The number of cases with a genuine reason to remove the spray foam is extremely small and in most cases where removal was carried out, no problems were identified, the roof was in good condition with no rot or additional moisture detected and the spray foam application had been correctly installed.

To find our more please read our blog here.

PIR and PUR insulation is used in a wide variety of applications including roofs, walls and floors as well as being widely used in off-site construction.

The thermal performance of a building is often defined as the total energy expenditure (per unit of the indoor floor area) needed to heat and/or cool the interior of a building to a minimum level of “thermal comfort”.

There are three values used when calculating thermal performance. These are lambda values, R-values and U-values.

With so many homes in England at risk of flooding installing an insulation product that won’t slump or sag when wet is an important consideration when building new homes or carrying out refurbishment projects. The use of closed cell insulation has long been advocated in flood risk areas. Find out more here.

There are different regulations for each of the devolved nations. These are the Approved Documents in England and Wales, the Scottish Technical Handbook in Scotland and the Technical Booklets in Northern Ireland. They provide guidance on different aspects of a building’s design and construction. Find out more here.

PIR/PUR boards are available from most large builders merchants. Many will be stocked under their trade names from some of our member companies.

Yes, PUR can be used as insulation for either partial-fill cavities or fully-filling cavities. For many years PUR injected into cavity walls has been used not only as a highly efficient insulant but also as a means of stabilising masonry cavity walls where wall ties have corroded or failed.

Insulation Manufacturers Association© | All Rights Reserved 2026

Designed & Built By Platform81