Rigid polyurethane (PUR) and polyisocyanurate (PIR) insulation products are highly effective, lightweight and easy to handle. Their excellent thermal conductivity and high strength to weight ratio, combined with great manufacturing versatility provides a wide range of products. As a result, PIR and PUR insulation products are the natural choice for most construction thermal insulation applications.

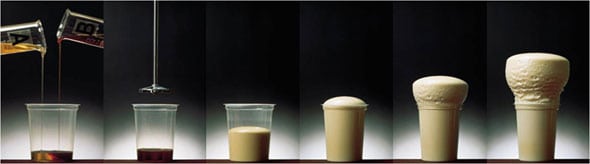

Rigid PUR insulation products are made by reacting a liquid polyol with a liquid polymeric isocyanate known as MDI in the presence of a blowing agent and other additives. The mixed components then react exothermally to form a rigid thermosetting polymer. Since the blowing agent evaporates during this reaction a rigid closed cell low density insulation product is created. Excellent insulation performance is achieved because the gas trapped within the closed cell structure has a very low thermal conductivity and there is minimal heat conduction through the solid cell walls due to the low density. Approximately 97% of the volume of the foam is trapped gas.

Rigid PIR differs from PUR in that it is produced with a slight variation in the chemical components. The resultant PIR insulation products exhibit increased fire performance and reduced combustibility and higher working temperature limits compared to PUR and when incorporated into building products, can meet some of the most demanding industry requirements.

Back to News