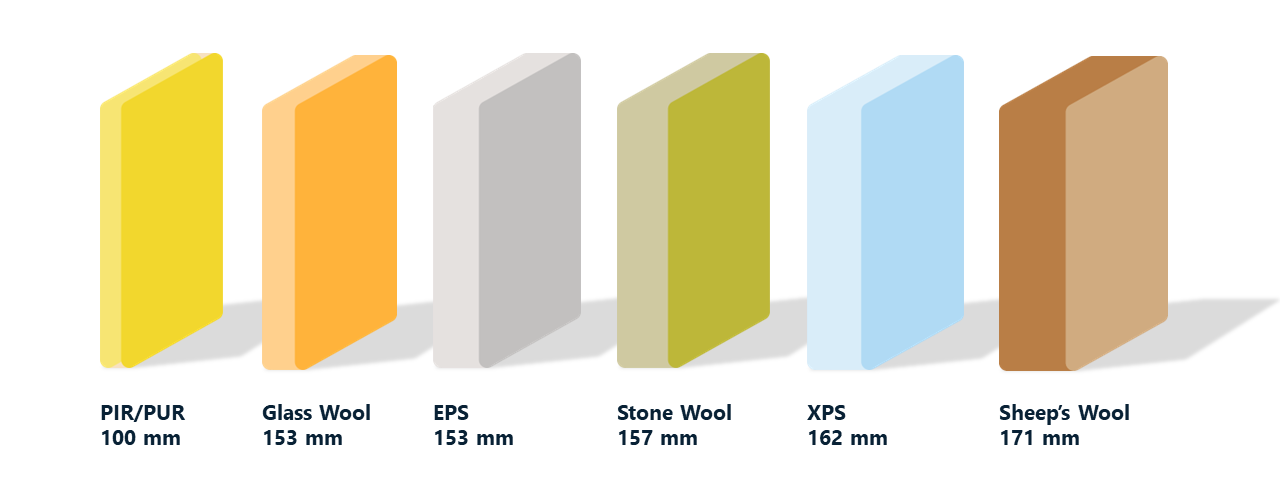

As well as being one of the most thermally efficient insulation materials available, PIR insulation has a high strength to weight ratio, is lightweight, meets a variety of fire performance criteria for differing applications along with good water resistance properties.